Key words: hammer crusher

summary:

Hammer crusher is suitable for crushing hard materials with compressive strength less than 250Mpa and medium hard materials. Such as limestone, dolomite, shale, gypsum mine, tombstone, coal mine stone and other medium hard and brittle materials, with large feed size and uniform discharge particle size, and can select and order sieve plate according to different needs of users. It is an ideal crushing equipment for mining, cement, building materials and other industries.

working principle:

The main shaft of hammer crusher is equipped with multiple groups of regularly distributed hammers, which form a rotor with turntable and hammer shaft. The main shaft is driven by motor and V-belt to make the rotor rotate. The centrifugal force generated by the rotation of the hammer spreads around. After large pieces of material enter the crusher from the feed inlet, they are hit by the high-speed rotating hammer head. The required materials are driven by the lower part of the crusher The castor bars are discharged from the gap, and the materials that fail to meet the requirements are left in the crushing chamber, which are repeatedly hit by hammers and materials until they reach the fineness.

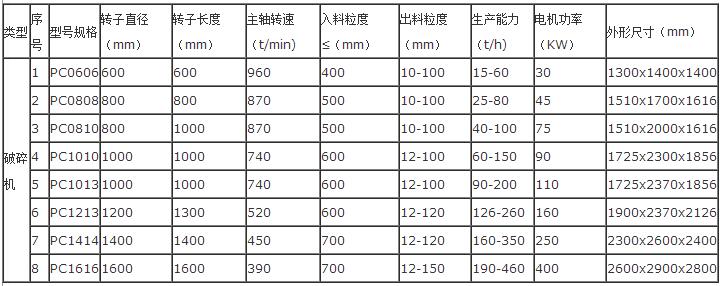

Note: model naming method (taking PC1010 as an example): P for crusher; C for hammer head; 10 for rotor diameter of 1000mm; 10 for rotor length of 1000mm.

Main technical parameters: