Key words: roll crusher

2PG double roll crusher

The double roll crusher is suitable for medium crushing and fine crushing of solid materials with compressive strength less than 300mpa and moisture less than 35%. It can be widely used in mining, thermal power, cement and ceramics, metallurgy, chemical industry, building materials and other industries. It has the characteristics of low maintenance cost, reliable performance, less dust and low noise.

The double roll crusher is equipped with two crushing rolls. According to the particle size required by users, the roller surface is divided into two forms: flat roller and surfacing roll surface. If the compressive strength of materials exceeds 200mp, the weighting type can be selected.

The flat roller surface machine is suitable for the fine crushing operation when the feed particle size is less than 80 mm and the finished product size is required to be 0.5-10 mm. For example, the use of pebbles, construction waste artificial sand; mining fine crushing iron ore, quartz stone; ceramic industry crushing raw materials; metallurgical industry crushing coke, quicklime; coking plant fine pulverized coal; chemical industry crushing various raw materials or similar crushing occasions.

The surfacing roller type is suitable for medium and fine crushing operation with feeding force less than 150 mm and finished product size requirement of 3-30 mm. For example, cement clinker, limestone and composite materials are pre broken before grinding in cement industry; steel slag, iron ore and silicon ore are pre crushed before grinding in coal water slurry industry; various ores are crushed to make non burnt bricks in brick making plant; electric coal is crushed in thermal power plant; or similar crushing occasions are mentioned above.

Working principle: 2PG double roll crusher

The double roll crusher uses the high extrusion pressure produced by the relative rotation of two high-strength wear-resistant alloy crushing rolls to crush the materials. After the materials enter the gap between the two rolls (V-shaped crushing chamber), they are affected by the extrusion force and shear force of the relative rotation of the two crushing rolls. Under extrusion, shearing and grinding, the materials are crushed into the required particle size and discharged from the discharge port.

Working diagram of 2PG double roll crusher

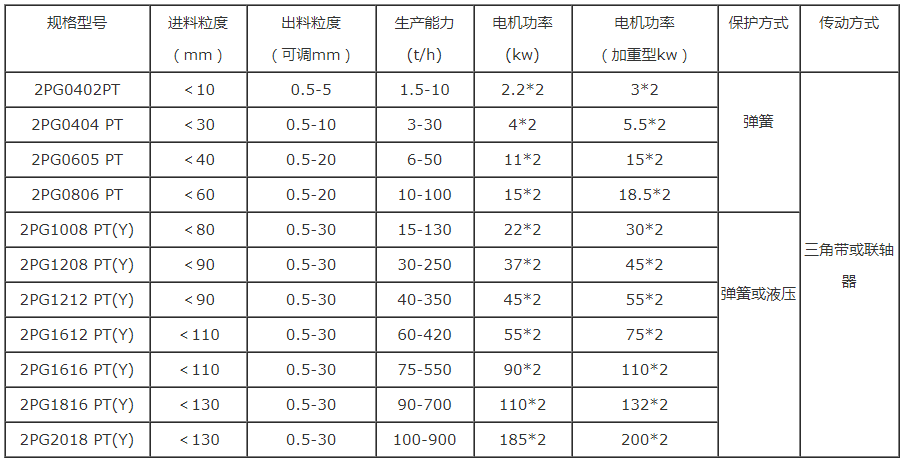

2PG對輥式破碎機....主要技(jì)術(shù)參數(shù):