Key words:high gradient plate magnetic separator

summary:

It is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with particle size less than 3mm. It is also used for iron removal of coal, non-metallic ore, building materials and other materials. The magnetic system of magnetic separator is made of high quality ferrite material or rare earth magnetic steel. The magnetic field intensity of the machine is very high. It integrates physical mechanics, fluid mechanics and magnetic mechanics. It can select some weak magnetic minerals according to the different magnetic properties of ores, such as pseudomagnetite, weakly magnetite, hematite, manganese ore and other weak iron ores.

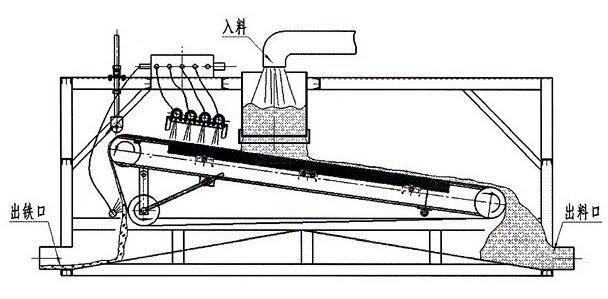

working principle:

The high gradient plate magnetic separator adopts belt separation structure. In the whole working area, the material can be magnetically stirred for many times under the drive of the belt. At the same time, the non magnetic tailings are removed under the washing effect of water flow. The magnetic minerals are transported to the demagnetization area of the plate separator by leather belt, so as to remove the magnetic minerals through the demagnetization device, To complete the mineral processing process, the whole machine power is small, the processing is big, the magnetic field intensity is high, and achieves the very good quality, can obtain the bigger benefit.

Technical features:

1. The surface magnetic field intensity is high, according to the different needs of customers can be customized in 6000-14000gs of various models of equipment.

2. The height of the working area can be adjusted to meet the needs of various terrain.

3. The belt structure has good separation effect.

Working diagram:

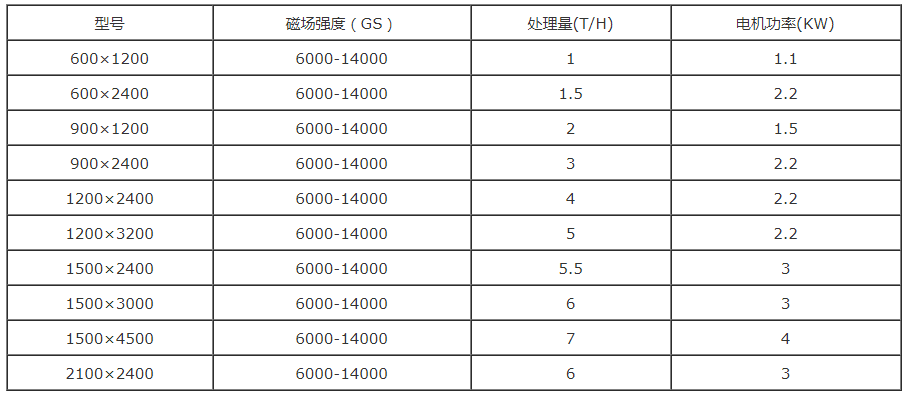

Main technical parameters: