Key words:Wet magnetic separator with strong magnetic roller

summary:

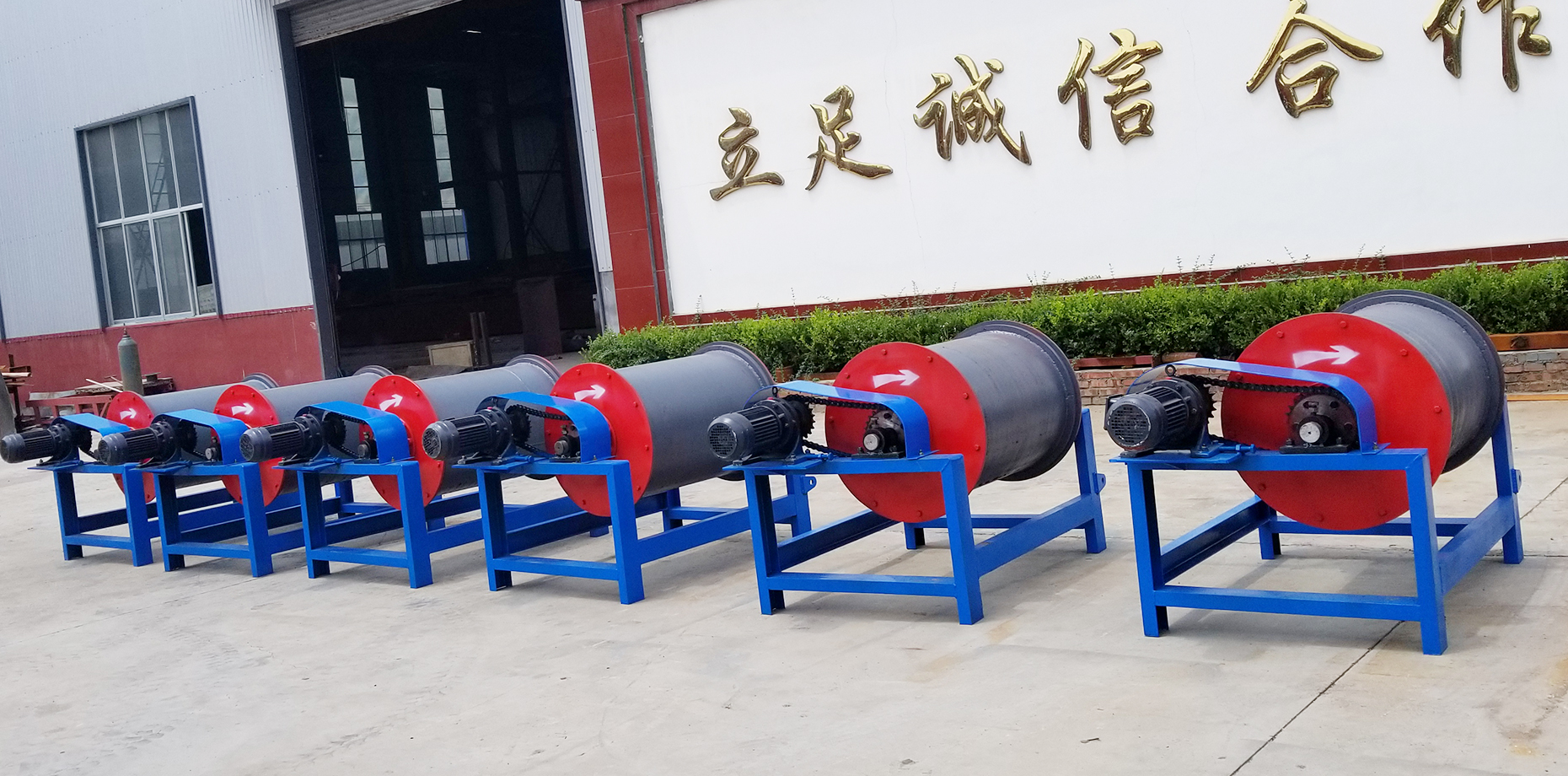

TLCH type strong roller wet magnetic separator is a combination type developed by our company according to many years of experience and customer's on-site demand, which can realize the combination of multiple structures or different magnetic field strength. The principle is that the materials enter the magnetic field area through the guide plate through the bin, and the magnetic minerals are adsorbed on the surface of the magnetic roller and rotate to the concentrate area. The brush will brush off the magnetic ore adsorbed on the surface of the magnetic roller and drop it into the concentrate hopper with the jet of high-pressure water. Some non adsorbed magnetic particles, non-magnetic particles and weakly magnetic particles will enter the next stage for re concentration, with a maximum of 10 rolls It can separate materials up to 10 times, especially for strong magnetic, medium magnetic and weak magnetic coexisting minerals.

Scope of application:

It is mainly used for roughing, scavenging and cleaning of fine weak magnetic ore. It can effectively treat manganese ore, hematite, pseudohematite, Specularite, siderite, manganese ore, chromite, goethite, limonite, siderite, chromite, niobium tantalite, ilmenite, wolframite, ferritite, apatite, yttrium phosphate, olivine, cuprammonite, hematite, biotite, epidote, serpentine, primary ilmenite, seashore placer, primary rutile Wolframite and nonmetallic iron removal.

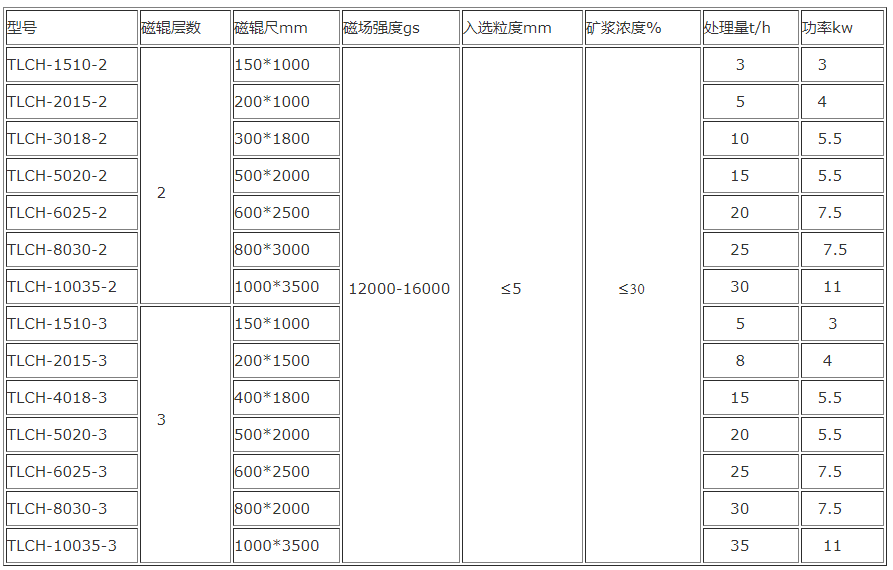

Main technical parameters:

The above data are for reference. The number of magnetic roller can be 1-10 rolls according to the demand, and the size of magnetic roller can be varied and combined according to the demand. The actual magnetic field strength should be determined according to the material conditions and sorting requirements. The processing capacity will vary with the number of magnetic roller, magnetic roller size and pulp concentration. The actual design scheme shall prevail