Key words:

summary:

Star type unloader is the main equipment for dust removal, air supply and other equipment feeding. It is suitable for powdery and granular materials. It is widely used in environmental protection, metallurgy, chemical industry, grain, food and other industrial sectors. Star unloader (also known as rigid wheel feeder, star feeder, air shut-off, rotary feeder, etc.

Star type unloader is also known as discharger, rotary feeder and air lock valve. Generally, the structure of star discharge is composed of rotor, impeller, shell, seal, reducer and motor with several blades. Small size, reliable operation, good sealing and wear resistance, our company can also make special-shaped star shaped unloader according to different needs of customers. When the impeller is driven by the transmission mechanism and rotates in the body, the powder materials falling from the upper separator (or hopper) will enter the impeller chamber through the feed port, and will be sent to the discharge port for discharge with the rotation of the impeller Continuous quantitative feeding and unloading. Steel impeller feeder is suitable for conveying and batching system in power plant, cement plant, chemical plant and other industries. It can be used for locking air or quantitative feeding when conveying dry powder materials. It can also be used for discharging ash under ash hopper of dust collector and air heater. It has simple structure, stable performance, convenient operation and maintenance, and is an ideal accessory in conveying, discharging and batching system.

Features of star type unloader:

1. Cycloid pin wheel reducer is adopted, and the transmission mechanism is simple and reliable.

2. The main body of the air lock is made of cast iron, which is resistant to high temperature and wear resistance, and is not easy to deform when the temperature changes sharply.

3. The air lock bearing and bearing support are far away from the shell, so the dust is not easy to enter the bearing, and can reduce the impact of high temperature materials on the bearing, and has a long service life.

4. The inner star impeller is made of 45 ᦇ steel, which is wear-resistant.

5. The upper part of the air lock housing is provided with an inspection hole for inspection in case of failure.

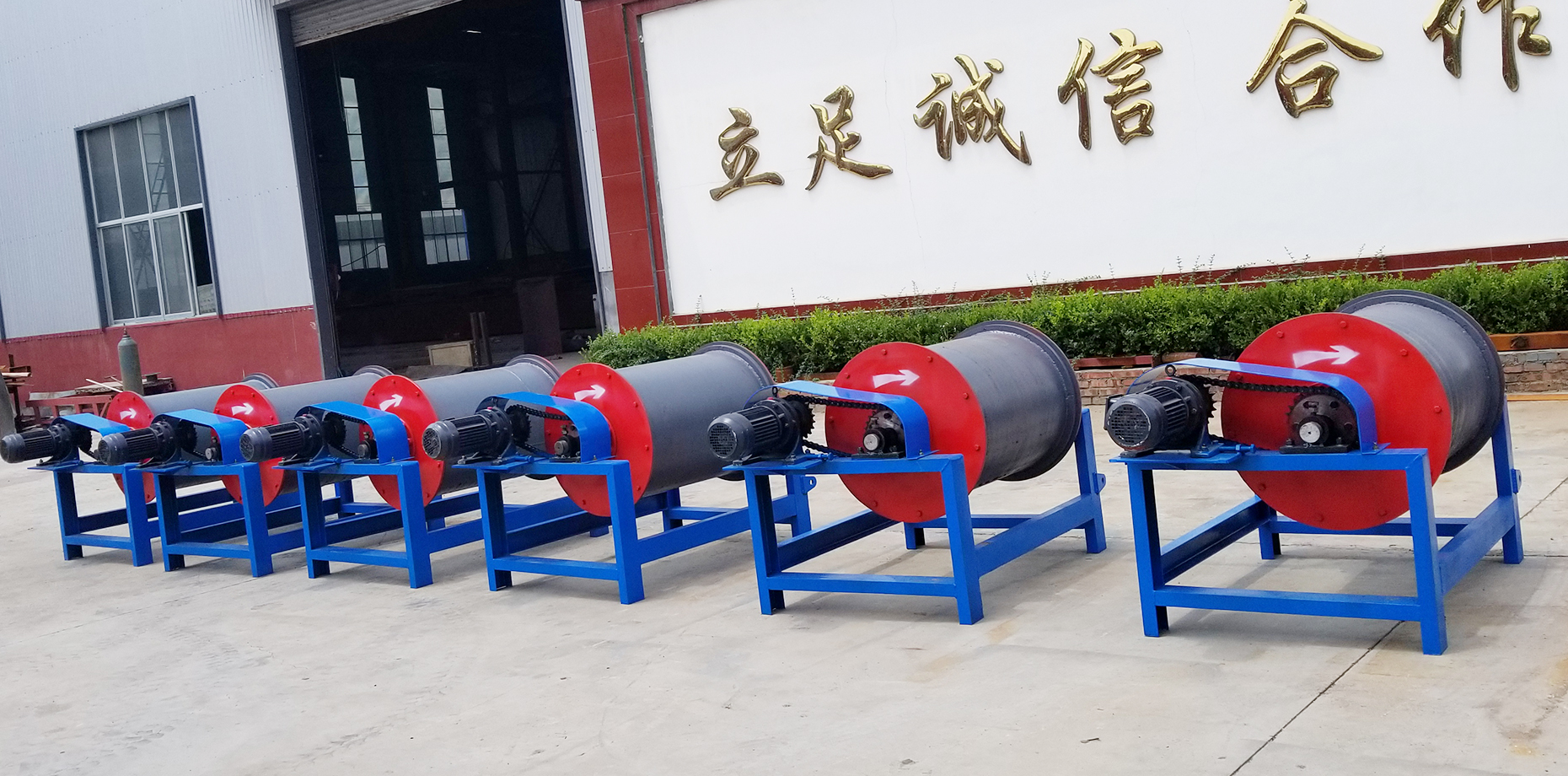

Production site: