Key words:

summary:

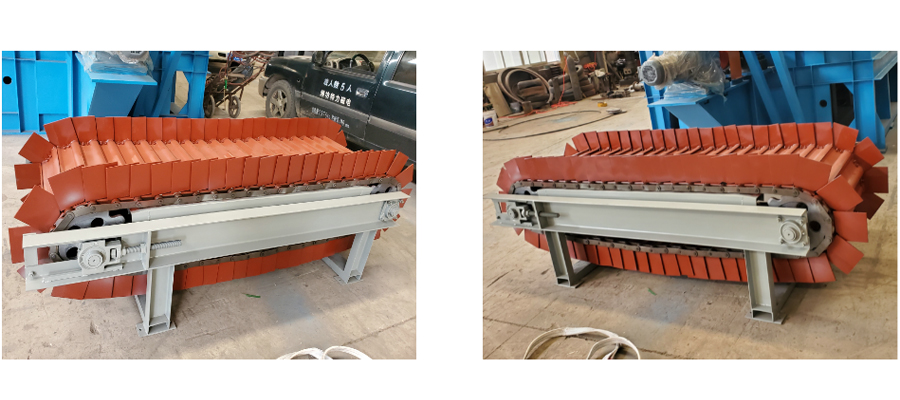

Chain plate quantitative feeder high temperature clinker chain plate quantitative feeder is an automatic quantitative feeding metering device developed for solving the measurement and control problems of high-temperature clinker in cement industry II. It adopts load sensor, with high measurement accuracy, reliable operation, simple maintenance and low maintenance, which is suitable for high temperature and boring transportation and measurement. The chain plate can be inlaid on the special tape, and the chain wheel can also be used to provide power. High temperature resistant chain plate is molded by die, which is durable and deformation free, advanced technology and high degree of automation. It is suitable for single machine and DCS distributed control system. It is an ideal equipment in automatic control batching system.

The equipment is suitable for bulk materials with high temperature or certain humidity or high friction force and poor fluidity, such as clinker out of kiln, high temperature clinker into grinding, clay, iron concentrate, slag, etc. It can be widely used in building materials, metallurgy, electric power, chemical industry and other industries.

Product advantages:

1. No need to change the belt, save the cost of the belt, reduce the cooling time and improve the production efficiency.

2. Thick material layer, low speed operation. Therefore, it has the measurement accuracy of stable operation and close to static state.

3. Replace the belt weigher, no need to change the host and software, with reliable frequency control technology.

4. The chain plate quantitative feeder has high automatic quantitative adjustment precision, wide adjustment range and low operation and maintenance cost.

Technical indicators:

1. Measurement control accuracy: the error can be better than 1%.

2. Working mode: continuous automatic

3. Working voltage: 380VAC ± 10% 50 Hz ± 2 Hz, 220 VAC below 2.2 kW.

4. Material temperature: < 450 ℃.

5. Interface signal: 0-10V or 4-40ma.

6. Reserved communication interface: RS485 / RS232.

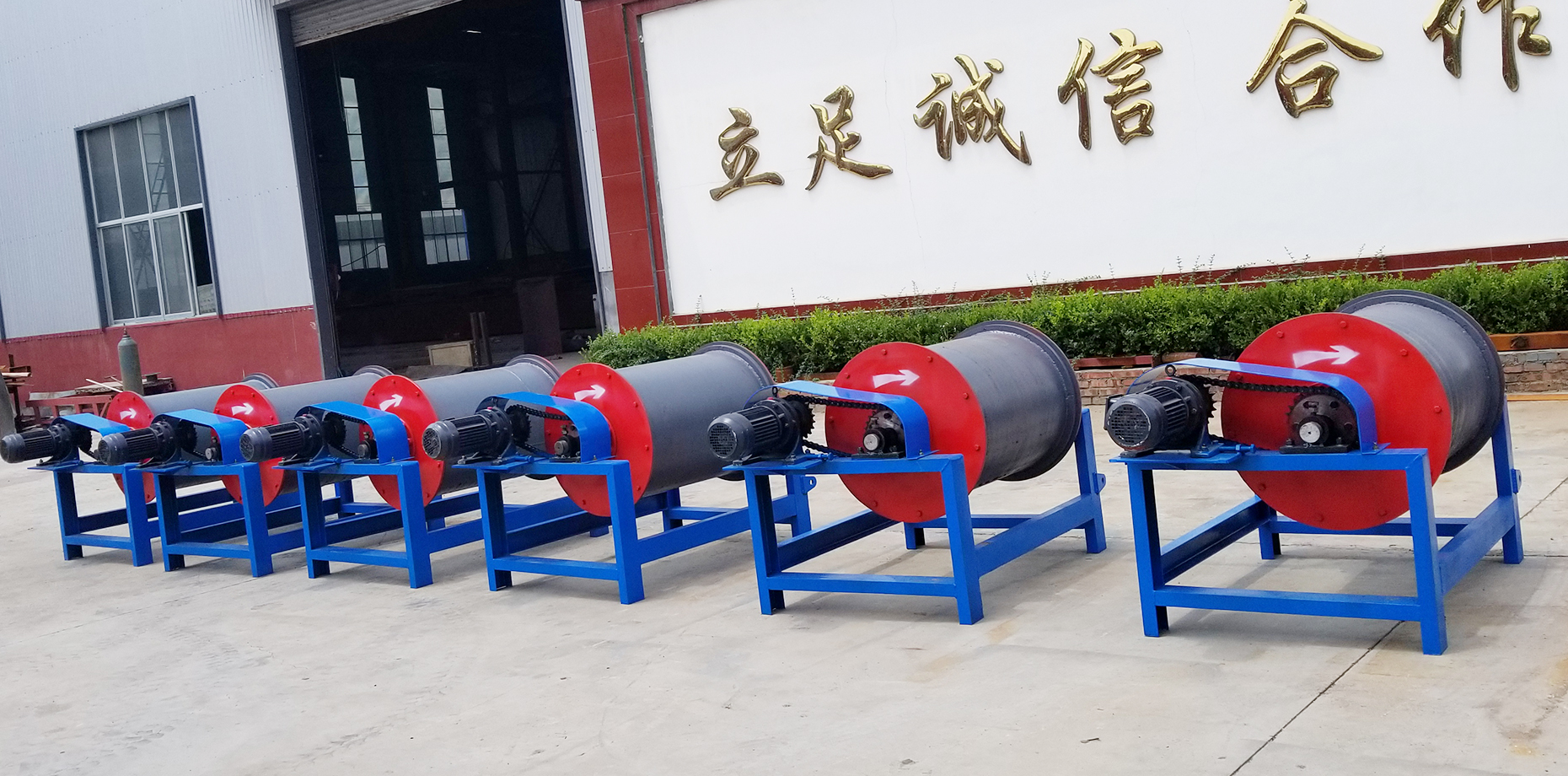

Production site: