Key words:ICS electronic belt scale

summary:

ICS-14 high precision electronic belt weigher adopts full suspension weighing bridge, digital signal transmission and processing technology, and the dynamic accumulative error is less than ± 0.125%. The electronic belt scale is suitable for internal and external settlement of enterprises, or other occasions with high precision requirements for symmetrical weight.

Belt scale structure:

ICS-14 electronic belt scale consists of four parts: ics-14 weighing bridge, weighing sensor, 60-12c speed sensor and speed measuring roller, yl2001 weighing controller.

working principle:

The weighing bridge is installed on the conveying frame. When the material passes by, the measuring roller detects the weight of the material on the belt conveyor, and acts on the weighing sensor through the lever to generate a voltage signal proportional to the belt load. The speed sensor is directly connected to the large diameter speed measuring cylinder, providing a series of pulses. Each pulse represents a belt movement unit, and the frequency of the pulse is proportional to the belt speed. The weighing instrument receives the signal from the weighing sensor and the speed sensor, obtains an instantaneous flow value and a cumulative weight value through integral operation, and displays them respectively.

Technical parameters:

The weighing bridge is installed on the conveying frame. When the material passes by, the measuring roller detects the weight of the material on the belt conveyor, and acts on the weighing sensor through the lever to generate a voltage signal proportional to the belt load. The speed sensor is directly connected to the large diameter speed measuring cylinder, providing a series of pulses. Each pulse represents a belt movement unit, and the frequency of the pulse is proportional to the belt speed. The weighing instrument receives the signal from the weighing sensor and the speed sensor, obtains an instantaneous flow value and a cumulative weight value through integral operation, and displays them respectively. System accuracy: ± 0.25%, weighing range: 1 ~ 8000t / h

Belt width: 500 ~ 2400mm, belt speed: 0 ~ 4m / S

Inclination angle of belt conveyor: < 6 ℃ (special materials ≤ 10 ℃) working conditions and installation conditions:

Ambient temperature: mechanical: - 20 ℃~ + 50 ℃; instrument: 0 ℃~ 40 ℃; power supply voltage: 220 V (+ 10 ‰, - 15 ‰) 50 Hz ± 2 ‰

The weighing sensor:

The load cell selected by ICS electronic belt scale is tension (pressure) sensor of resistance strain gauge. Main technical parameters of load cell:

Nonlinearity: less than 0.05% of rated output repeatability: less than 0.03% of rated output hysteresis: less than 0.03% of rated output

Temperature sensitivity: ± 0.003% at zero value, ± 0.004% at full value, safety overload: 150 ﹪

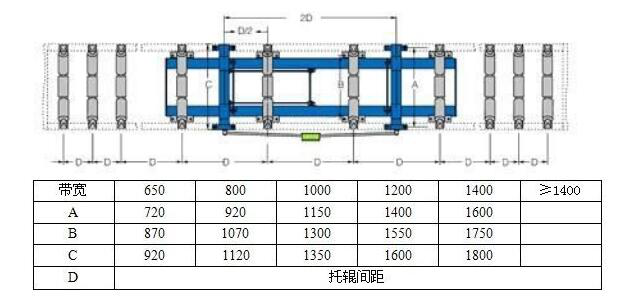

External structure and installation dimension of electronic belt scale: