Key words:

summary:

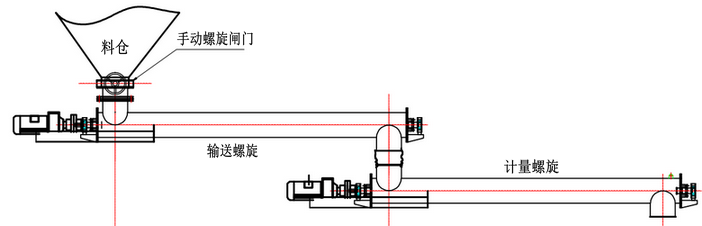

The speed regulating screw metering scale is a kind of rotating screw which is used as a tool for material pushing and conveying. It can continuously transport materials in a closed pipe and control and measure the conveying process at the same time. This series of spiral electronic scale has reasonable structure, stable and reliable operation, good sealing, no dust flying, no leakage, conveying length of 1-8 meters, high conveying efficiency and convenient maintenance. The instrument has the functions of zero point automatic tracking, data protection, menu prompt operation, analog current output, etc., and is equipped with RS-485 communication interface, which can realize centralized control of industrial computer.

Main features:

1. It is specially used for the measurement and control of powdery materials.

2. The feeding screw has a unique steady flow structure, and the feeding material sinks evenly in the whole feed inlet section, which is not easy to arch and flush.

3. Cycloid needle wheel reducer ensures long-term stable operation.

4. The structure of variable diameter and variable pitch is adopted in the steady flow screw, which effectively solves the problem of material flushing (the output > 60t / h adopts double pipe steady flow).

5. The measuring screw scale adopts three high-precision sensors (tension) to weigh directly, which successfully solves the error caused by lever weighing and greatly improves the measurement accuracy.

6. Using digital acquisition module, the effective resolution is as high as 1 million; the acquisition rate is 50 times / S; the annual drift is less than 50ppm; the temperature drift is less than 50ppm.

7. Sealing structure to reduce dust emission.

Technical indicators:

1. Measurement accuracy: ≤± 1%

2. Control accuracy: ≤± 2%

3. Speed regulation range: 10:1

4. Working mode: continuous

working principle:

The speed regulating screw electronic scale is mainly composed of screw scale body, weighing sensor, signal transmitter, frequency converter, control regulator and motor. When conveying materials by screw scale, the weighing sensor converts the weight of materials on the weighing section into voltage signals and sends them to the signal transmitter. The control regulator is used for processing and displaying, and the instantaneous flow and cumulative flow of materials passing through the screw scale are obtained. The control regulator of the screw electronic batching scale outputs 4-20mA current to the frequency converter to adjust the motor speed, so as to achieve the purpose of quantitative feeding.

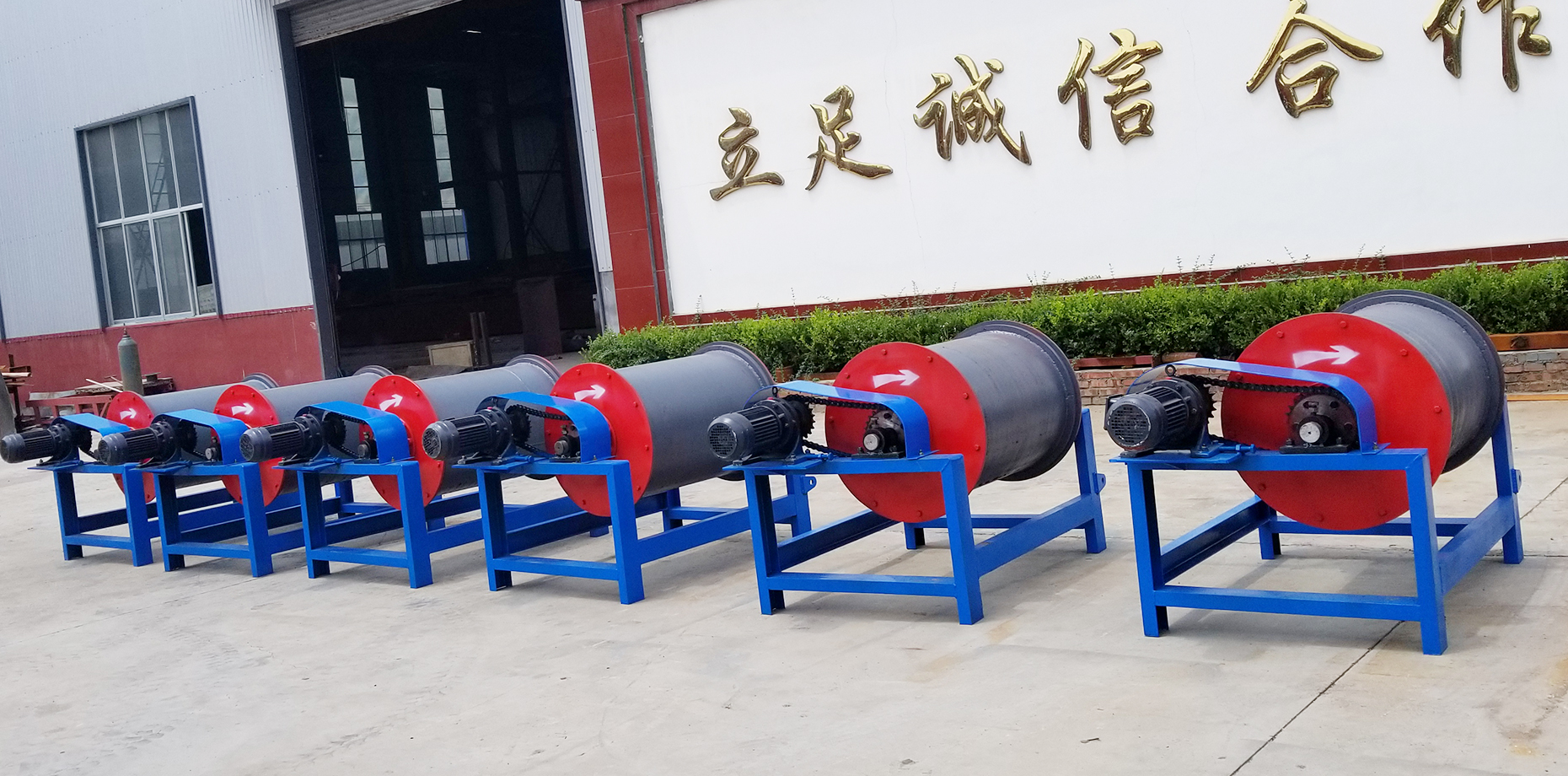

Production site: