Key words: HS disc tailings recovery machine

summary:

The main components of the raw iron ore have been enriched in the concentrate after being treated by the beneficiation operation, and some of the secondary components or other metals of the ore can also be recovered after comprehensive treatment. Therefore, the remaining part of the product contains very low useful components, which is called tailings. It should be pointed out that there is still a large amount of useful iron medium in tailings.

A concentrator with a design capacity of 6 million tons per year (6 million T / a), the grade of raw ore is 30%, the grade of concentrate obtained is 60%, the annual production of concentrate is 2.2 million tons, the tailings volume is 3.8 million tons, and the lifting iron content is about 38 tons. After the development of a multi disc magnetic separator for recovering useful iron in tailings, the flavor of iron can reach 35%, because it is the tailings in the upper section, and its particle size is pulled into rough grinding and fine grinding At least 80000 tons of qualified iron concentrate can be obtained by low intensity magnetic separation.

Application and characteristics of the product:

1. The equipment has the advantages of high recovery rate, small volume, easy arrangement, large processing capacity and remarkable economic benefits.

2. The equipment is especially suitable for the re separation of waste tailings, turning waste into treasure, extracting concentrate and reducing environmental pollution.

3. Iron concentrate is directly recovered from tailings of magnetic separation plant, iron Lin is recovered from waste water of rolling mill, iron concentrate is separated from tailings accumulated for many years, iron ore is separated from inland river beach or seashore placer, and weak magnetic iron ore such as oxidized iron ore is separated.

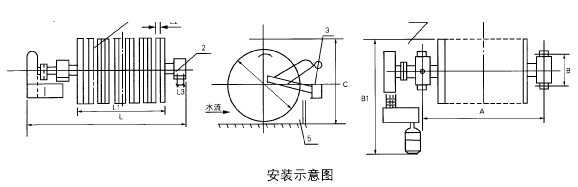

Installation diagram:

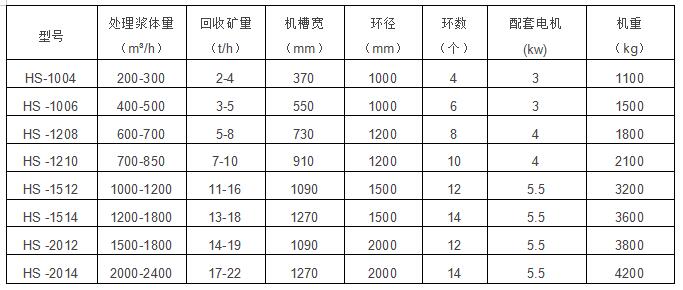

Main technical parameters:

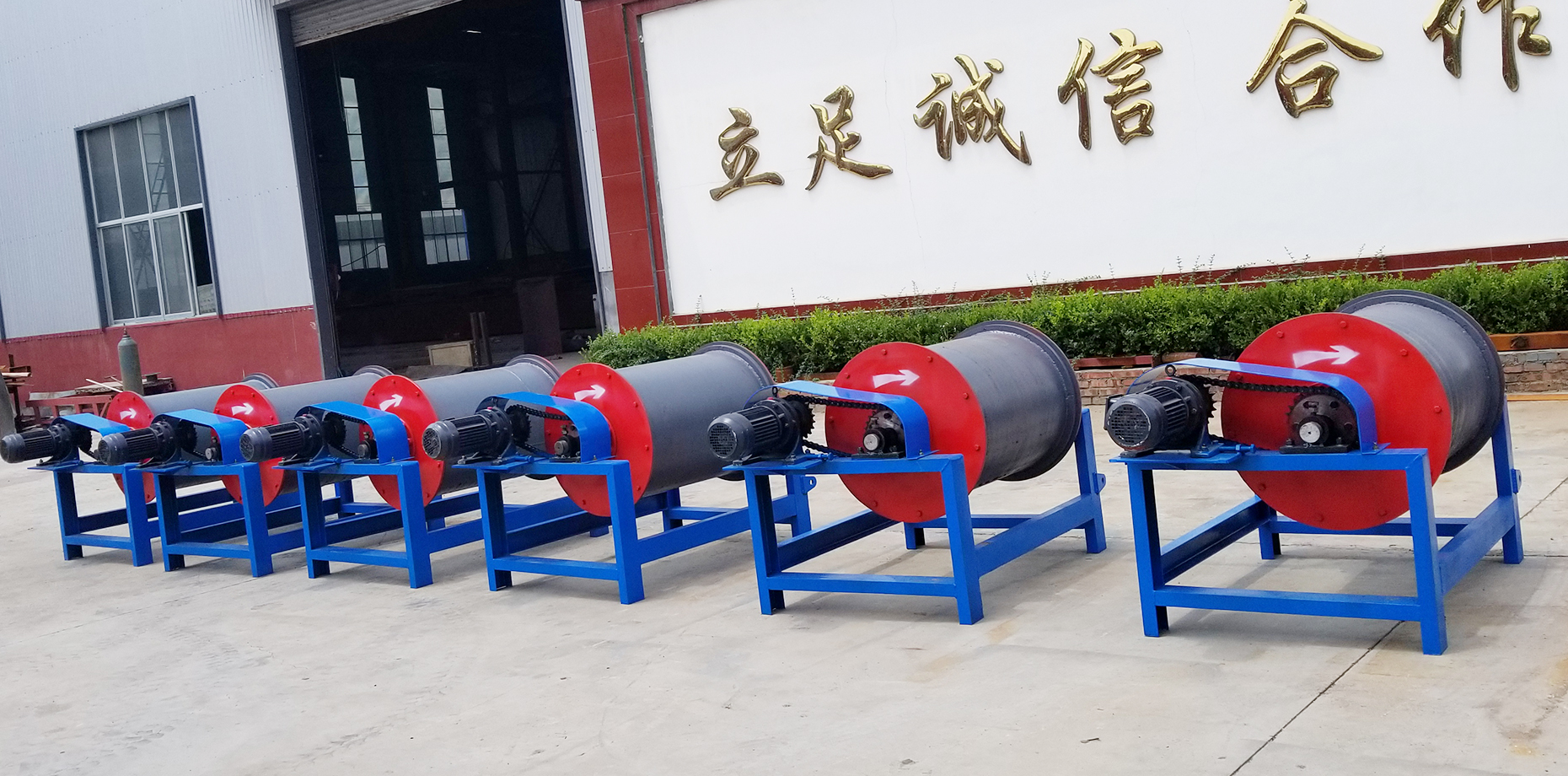

Production site: